Best Dust Collector for Woodworking?

A Lung Cancer Scare Motivated Me to Find the Best Dust Collection System for My Woodworking Shop

By Joshua Farnsworth | Aug 25, 2022

Best Dust Collector for Woodworking?

A Lung Cancer Scare Motivated Me to Find the Best Dust Collection System for My Woodworking Shop

By Joshua Farnsworth | Aug 25, 2022

In this video and article I talk about my experience in finding what I consider to be the best dust collector on the market.

I’ll also share my recent health scare that motivated me to stop ignoring the importance of having an effective dust collection system.

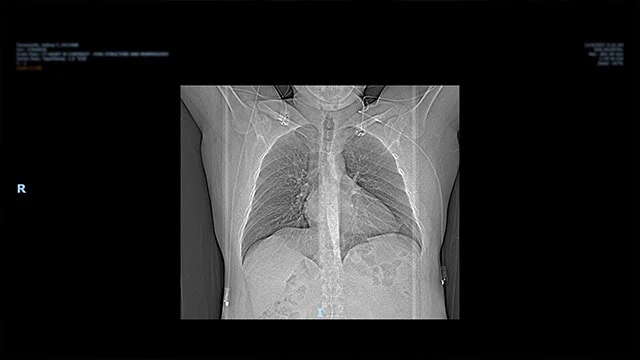

My Recent Lung Cancer Scare

Recently I had a surgery that required a CT scan on my chest. After my surgery, the radiologist notified me that the CT scan showed unusual nodules on one of my lungs, which may be a sign of lung cancer.

As you can imagine, that’s not great news to get right after a surgery. They told me that I would need another CT scan after a few months to see if the nodules were growing or not.

So during those nerve-racking months, I had time to think about what could have caused this issue. I figured that if I did have lung cancer, it wasn’t from smoking, because I’ve never done that…but it would have been caused by exposure to so much wood dust.

My Failed Attempt at a Cheap DIY Cyclone Dust Collector

I had always used dust collection in my workshops over the years, but always did it as cheaply as possible. Sound familiar?

When you’re fairly young, you think more about your budget than you do about health risks. For years I had been using cheap single-stage dust collectors, because I figured that they would be better than no dust collection.

Which is true, but it doesn’t make it safe enough to prevent lung diseases caused by sawdust. So a few years ago I attempted to improve the air quality in my workshop by modifying my cheap single stage Grizzly dust collector into a DIY cyclone system, using a special lid and trash can.

Cyclone technology basically means that you’re using a two-stage dust collection system where the bulk of the wood chips and sawdust are first dropped into a can, and then the finest particles are carried away for filtration. This keeps your dust collector from having to filter all the big stuff.

My DIY dust collection system seemed like it would work great in theory, but in reality, this system turned out to not work very well. No matter how much I modified the plastic lid, I couldn’t get it to do a good job at collecting most of the big wood chips and sawdust, so most of it was thrown at the air filter.

Also, my dust collector didn’t have enough CFM to keep up with my machines. CFM is just a measure of airflow. So both of these problems led to fine dust escaping through the air. And anyone who has used a cheap bag-style dust collector knows how much fine dust gets blown into the air when the collector starts up. That’s the fine dust. So the purpose of having a dust collector is kind of missed.

Which is the Best Dust Collection System Brand?

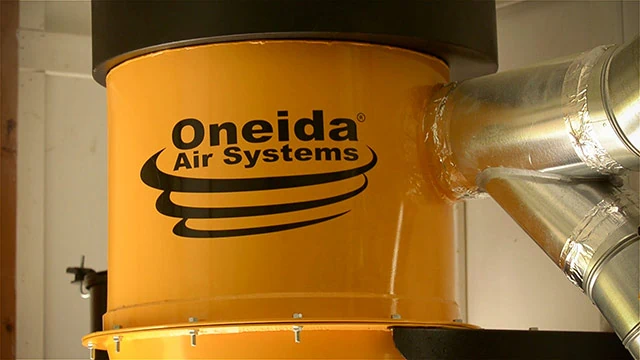

So this health scare finally motivated me to upgrade my dust collection system. After talking with friends and reading reviews, I settled on the company Oneida Air Systems.

Most dust collectors are made by companies that make a thousand other products, but Oneida focuses only on dust collection. They are widely considered to be the leader in dust collection systems, and the majority of woodworkers feel that Oneida makes the best dust collector systems for woodworking.

I ordered the 5 HP Oneida Dust Gorilla dust collector and a custom ductwork system, so I’ll primarily talk about that dust collection system. But I’ll also talk about some other Oneida dust collector systems for woodworking, and will even show you a cool, affordable option that will work for upgrading your single stage dust collector into a two-stage cyclone style dust collector. One that actually works!

Why I Chose the Oneida 5HP Dust Gorilla Pro Dust Collector

Before I had settled on a specific dust collection system, Oneida asked me about all of the specific machines in my workshop, the dust port sizes, distances between machines, and the electrical power that I have available at my panel.

Once they understood all of this, and my desired shop workflow, they recommended the 5 HP Dust Gorilla. You may not need this much horsepower in your workshop, but I have a 16-inch Felder AD-941 machine that works as a jointer and thickness planer.

It puts out a serious volume of wood chips and sawdust, especially when I joint and plane really wide boards. This is the biggest wood dust-producing machine in my workshop.

My previous 1-1/2 HP dust collection system really struggled to keep up with the amount of wood that I put through it, but now I have so much dust collection power that I get virtually no chips or dust escaping my planer.

And the high efficiency cyclone on the Dust Gorilla has a separation rate of over 99%. That’s infinitely better than my DIY dust collection system!

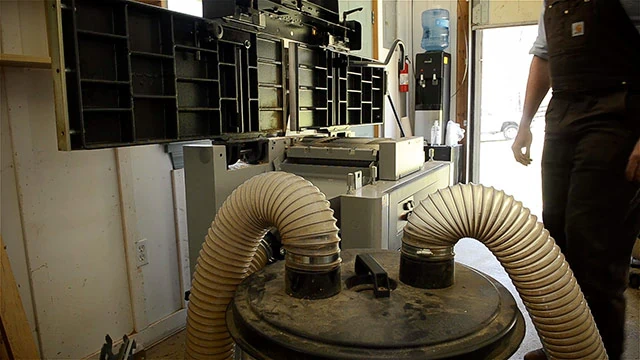

And as you can see here at the end of my dust collection ductwork, I can close the blast gate to my Felder machine, and open the blast gate that runs a hose to my band saw.

I’ve setup a custom system with hoses on the back of my band saw, and it works quite well. Most band saws aren’t designed very well for dust collection, but I have so much sucking power now, that it works quite well.

My other big dust collection requirement (and difficulty) is on my SawStop table saw.

I close the other blast gates, and then go over to the ductwork near the Gorilla, and open up this blast gate for my table saw.

It runs down to my SawStop table saw dust port. This Dust Gorilla keeps up really well with the sawdust and wood chips that come down into the table saw cabinet. But my main challenge that I still need to remedy, is collecting the sawdust that exits above the table saw.

I have tried using the SawStop overarm dust collection system, as you can see here, but it does almost nothing to keep sawdust and wood chips from flying in the air.

I have plenty of suction power from the Dust Gorilla, but SawStop’s system seems to be flawed. SawStop also has a $500 floating overarm dust collection system, but I’ve heard a lot of people say that it also doesn’t work great…and it costs over $500 (see it here). So that option is a no-go. If the Oneida folks are watching this, maybe you can make a good overarm table saw system?

Another exciting option that I designed with the Oneida engineers, was a way to collect wood chips and sawdust from my lathe and drill press.

I close the table saw blast gate at this tower, and then open the blast gate that goes to my lathe. I’m still experimenting with different vent hoods, but this is the setup I have so far for my wood lathe:

And this is the setup I have for my drill press:

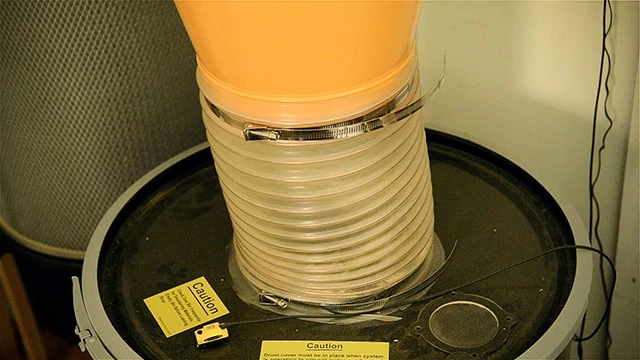

Down here is where the Dust Gorilla expels the sawdust and wood chips:

Some people will send the sawdust to an outside storage bin, which sounds cool, but that wasn’t an option for me. Because of the amount of wood that I mill up, I opted for the 55 gallon steel drum, as opposed to the 35 gallon drum.

But either option is far superior to the frustrating plastic bags. Not only are the bags difficult to remove and replace, but they tear easily, and get holes all the time. You can see that’s why I have so much duct tape on my bags!

And a really cool feature that came with my dust collector is the Dust Sentry™ Bin Fill Level Indicator.

The sensor points toward the sawdust in the drum, and a warning light lets me know when my drum is getting full.

If you have your own barrel, you can certainly hook it up to the Dust Gorilla, with some modifications.

I also decided to mount my Dust Gorilla to the wall, but other people opt for mounting it to a stand.

And this is the high quality filter where the finer dust goes after the big pieces dump into the drum.

Whichever brand of dust collector you buy, make sure you get one that comes with a HEPA certified filter that filters the finest dust down to 0.3 microns. That’s really small.

I’m not going to pretend to be one of those engineer guys who spends hours comparing technical specifications between machines. I’m actually a pretty simple-minded guy. But there is one technical feature really stood out to me about this dust collection system. I’ll try to explain it as simply as I can..or at least as best as I understand it:

As I touched on earlier, air volume moving through a dust collection system is measured by “CFM”, or Cubic Feet Per Minute. Most dust collector systems for woodworking have motors that run at a fixed speed. This isn’t very efficient, especially if your machines are far away from the dust collector, if they have smaller hoses & ports, and if you have multiple blast gates that you keep closed.

These traditional dust collectors will draw fewer electrical amps under these conditions, reducing the sucking power. But this Dust Gorilla uses Oneida’s patented SMART Boost® technology, which essentially increases the fan speed under those circumstances, to maintain a maximum suction power.

Even to my limited technical understanding, I could see how much better a system like this is!

Other Oneida Cyclone Dust Collectors

Oneida has a wide range of dust collector systems for woodworking shops, which you can see here. But rather than trying to figure it out for yourself, I would recommend calling or emailing Oneida to tell them about your workshop so they can help you understand the best system for your shop.

I thought I had nailed down the best dust collection system for my workshop through my own research: the Oneida Supercell High-Pressure Dust Collectors.

But they patiently explained the technicalities of why that wouldn’t be the best option for my workshop and machines. They aren’t trying to sell their customers their most expensive dust collection system. They want to get them the best system for their specific workshops and machines. That really impressed me.

Below I’ll link to some great articles that they sent me to read, that simplified the process of choosing a dust collection for your woodworking shop.

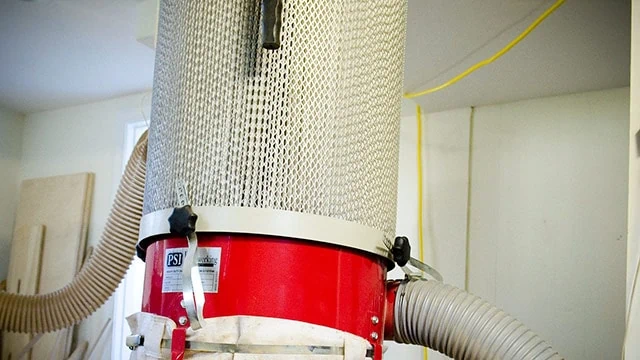

Oneida Dust Deputy: How to Convert a Single Stage Dust Collector into a Cyclone Dust Collector

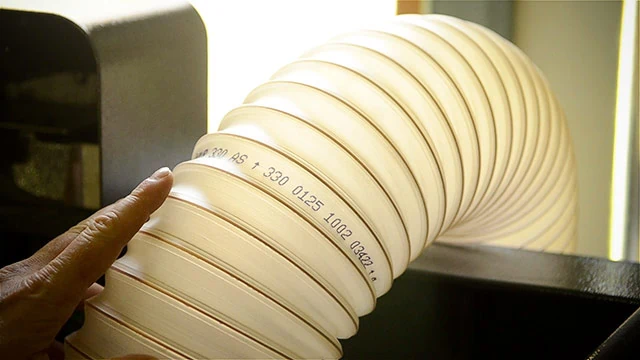

Remember how I tried and failed to convert my cheap woodworking dust collector into a two-stage cyclone dust collector? Well, Oneida came up with a much better solution. Even though I was upgrading to the 5 HP Dust Gorilla collection system, Oneida still sent me their Super Dust Deputy cyclone conversion kit. It attaches to your single-stage dust collector, and properly separates the woodchips and sawdust into your garbage can or steel drum.

I tried it out on my old dust collector, and it worked much better than my DIY cyclone experiment. The machines in my workshop are still too powerful for my old dust collector, so this isn’t a great option for me. But it may be a great option for woodworkers who are on a tight budget, who already have a single-stage dust collector, and who don’t have high-powered woodworking machines.

Oneida also sent me a smaller version of the Dust Deputy that’s made for shop vacs. This is working great for me, because I use a shop vac when I’m using a power router or vacuuming my workshop. It works great hooked up to my router table.

A Cool Dust Collector for Workbenches

Before I show you the installation of my new dust collection system, I wanted to share one more ingenious dust collection invention that Oneida sent to me. They know that I have 10 workbenches in my traditional woodworking school and that some of our classes involve extensive sanding and rasp work.

So they sent me a couple of their BenchTop personal dust collectors to try out in my classes. This has been a game changer in my workshop.

I simply set the dust collector on a workbench, turn on the motor, and then I can start sanding or rasping. The powerful motor sucks the sawdust out of the air, and into the filter.

This was a technology that I never even knew existed. Now I don’t do any hand sanding or power sanding in my workshop without a BenchTop dust collector on a workbench!

Setting up the Dust Gorilla Pro Dust Collector

In the following video I show the process I went through to configure and setup my Oneida Air Systems 5HP Dust Gorilla Pro SMART Boost Dust Collector, and my accompanying ductwork.

Conclusion

I hope my journey has helped you to increase your safety and health in your workshop. I am happy to announce that my follow-up CT scan showed that the nodules on my lungs had not increased, and I am most likely cancer free. Please comment below and let me know about your experience with dust collection in your workshop!

I agree with the above by Joshua Farnsworth I have the three horsepower Oneida system, engineered by Oneda and also wall hung. It has worked very well since installation several years ago. I suggest not buying larger than 6-inch ducting in one-person home shops. My shop is 24 by 36 and 8″ is unnecessarily large. I use a very fine filter that works splendidly. But since I live in a rural farming area, were I to do it again, I… Read more »

Hi, Josh. Glad you’re doing well. Here’s hoping your experience and advice will help younger woodworkers make a healthy start. All the best to you and yours.

Glad to hear you are doing OK, and that you have added a more serious DC. Woodworking is inherently dangerous and can add up to serious breathing issues after decades of working in an overly dusty environment. But in reality, over 50 years of woodworking the only DC I have found to clear the air of fine particles were those that expelled the used air outdoors to free air. None of the low end-high end DC I have installed ever… Read more »

Your struggles finding good dust collection solutions at some machines like your table saw and lathe underscore why even with the BEST dust collector, a personal respirator should be warn EVERY time you use a power tool to shape or cut wood, and for at least an hour afterwards in the shop. A couple tests of the air quality in your shop with a particulate air meter, after a few table saw passes, will put the fear of God in… Read more »

Joshua,

First, glad you do not have lung cancer!

Second, great job explaining dust collection. One of the the reasons for switching to hand tools only was the many shop safety/ health issues such as dust, whirling saw blades etc. Dust in particular since it is something not thought of as much as how close are my fingers to that blade etc.

Matt

Joshua, Thanks for sharing your scary experience. It comes home to me as I currently have no dust collection in my basement shop, which has reached a tipping point after adding a DeWalt Planer (the one with the fan-assisted chip gun). I have been noodling over the best system for my needs and, while I have not quite decided between a 2 HP or a 3 HP system, all the advice in your current post dovetails perfectly with my experience.… Read more »

Thanks for your comment! Regarding safety concerns between men & women, I’m not too sure, since we mostly use hand tools in our classes. But I have noticed that most women who take classes in our school tend to be very serious about learning, rather than just having an enjoyable class.

Great news regarding your none growing nodules! I guess being able to open up my shop to the outdoors won’t cut it. Thanks for the info.

Thanks for highlighting the importance of real shop dust collection. Microscopic wood dust causes serious, irreversible lung damage. For table saw dust collection, check http://www.TheSharkGuard.com. For in depth research on shop dust collection, I think Bill Pentz is the expert, http://www.billpentz.com. I Have a ClearVue dust system, and added a cheap ($100) air quality detector for my shop. It probably isn’t scientifically accurate, but it lets me know if the air is getting out of control. It measures microscopic dust… Read more »

Good to hear you’re okay. Thanks for the encouragement to set up a solid dust-collection system. I’m setting up a new shop and I’ll take this advice to heart! I live in central Minnesota and I love to see new videos and ideas from your shop.

Joshua, Glad to hear the favorable prognosis! So This is not meant as a torch or troll. I a retired engineer with a hobby of woodworking. I became seriously interested in dust collection a decade ago and read most of what I could find on the subject. So I’m interested in your search. The clearest and best thought out information that I found is Pentz’s extensive web site. He addresses the problems that you experienced: https://billpentz.com/woodworking/cyclone/index.php#index.php I then found Clearvue cyclones by his reference… Read more »

Joshua, glad to read that your health scare was not cancer. I too know the terror that that revelation can cause, for both you and your family. Thanks for the review of the dust collection system by Oneida.

About 15 years ago I had the same problem trying to collect dust around the top of the blade. At that time I had a unisaw with an after market riving knife. I attached a Felder guard to the riving knife trying to mimic the way it was set up on the Felder table saws. It worked fairly well. I now have a small Felder and I am pleased with the way it works. One of the things I like… Read more »

Thanks for sharing. Glad you’re doing better.

The cancer scare is definitely worrisome. I wish you the best. I have that exact same Grizzly and trash can with lid. And yes, it’s pretty pathetic. Fortunately, I also have a 1400 CFM attic fan I permanently mounted in a window, conveniently just above the Grizzly collector, where the glass was already cracked. It pulls a huge amount of air through the shop, either from the house above or an open door. It goes on before the Grizzly I… Read more »

Maybe should consider a Dylos particle counter. You’ll be surprised by what creates the most dust, sweeping and vacuuming up! The grinder creats crazy amounts of dust. The Dylos shows the guys on video-shows that wear a mask during the 5 min of sanding, only to pull off the mask, are idiots. Without an air cleaner running, it is more than 2 hours for the dust levels to drop to moderate levels. If you get a Dylos, note that I… Read more »

Maybe should consider a Dylos particle counter. You’ll be surprised by what creates the most dust, sweeping and vacuuming up! The grinder creats crazy amounts of dust. The Dylos shows the guys on video-shows that wear a mask during the 5 min of sanding, only to pull off the mask, are idiots. Without an air cleaner running, it is more than 2 hours for the dust levels to drop to moderate levels. If you get a Dylos, note that I… Read more »