How to Choose the Best Spokeshave and Woodworking Hand Tools for Curved Work

By Joshua Farnsworth

This hand tool buyer’s guide will focus on hand tools that are used for creating and refining curved work in furniture making. Below you’ll read an introductory explanation of these types of hand tools, and then I’ll jump into the hand tool recommendations:

Different Types of Curved Woodworking Hand Tools

Below I’ve listed the three main types of tools used for making curves on furniture parts while woodworking, including spokeshaves, rasps & files, and drawknives.

SPOKESHAVES

Spokeshaves were originally used for making spokes on horse carriages, but are a very common and useful tool in chair making, cabinetmaking, or anywhere else where curves are involved. The also work well for putting bevels on edges of straight pieces.

RASPS & FILES

Often mistaken for files, rasps are used for shaping wood using hundreds of little metal hooks. Rasps are especially helpful for shaping the handles of new handsaws and handplanes. Files aren’t used for shaping, but for smoothing the wood, and are usually used after rasps to smooth out the rasp marks.

DRAWKNIFE

A drawknife is used for quickly and efficiently shaping green wood, usually held in the vises of a traditional shaving horse. Drawknives come with different handle angles, to make work more suitable for either bevel up work or bevel down work.

Buy 1-2 Spokeshaves

What is a Spokeshave?

A spokeshave is basically a small handplanes used for shaping and smoothing curved wood. The spokeshave body holds an adjustable blade rigidly against the bed, in a very similar way to a handplane. As mentioned above, spokeshaves were originally used for making wagon wheel spokes, but have moved into being used for other types of woodwork.

What Spokeshaves Do You Need for Woodworking?

Opinions vary on which spokeshaves you need for woodworking, because many people use spokeshaves for different tasks. I will try to explain which spokeshaves excel at certain types of work, and then you can make the decision about which spokeshaves to buy.

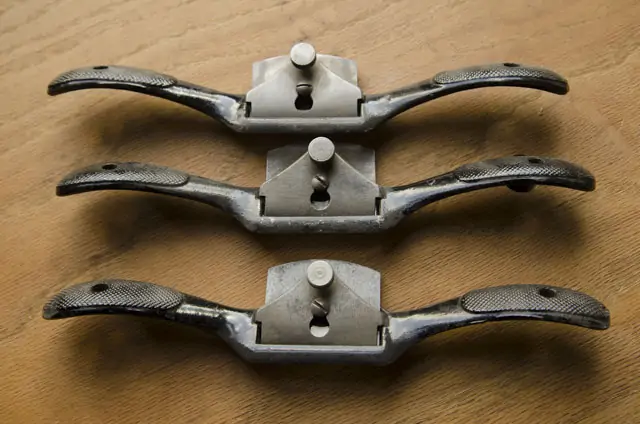

I like to have at least two spokeshaves, one with a flat bottom and set for taking more of a rough cut, and and one set for fine cuts. The fine cut spokeshave can have either a flat bottom, or (as I prefer) a slightly rounded bottom, for getting into curves. Many of the modern budget-friendly spokeshaves have poor machining, don’t have a bed that’s flat enough for stability, and don’t have good tool steel for the iron. There are a couple modern spokeshaves that can be modified to work well, especially with a good replacement blade that will hold a nice edge.

What are the Best Vintage Spokeshaves?

Antique spokeshaves are usually my preference, and antique wooden spokeshaves are really sweet if you can get them tuned up and get a tight mouth. However, before buying antique wooden spokeshaves, make sure the wooden body isn’t split. A couple people have done pretty good tutorials on how to sharpen wooden spokeshaves (check YouTube).

My favorite vintage, all metal spokeshave is the Stanley No. 151 spokeshave (also manufactured as the Record A151 spokeshave). It is probably the most popular and best-designed spokeshave. Hand tool expert Jim Bode said of the Stanley 151 spokeshave:

“The best-selling spoke shave of all time. A totally no-nonsense shave with dual micrometer like adjustments that allow you to take thin shaving on one side and a heavier cut on the other, if you want to. Easy to sharpen and easy to find replacement blades. Works great on flats, convex, and even concaves greater than 8 inch radius.”

Another very popular, though not as easily adjustable spokeshave is the vintage Stanley No. 51 spokeshave (pictured below). If tuned up, these smaller spokeshaves work great, and are cheaper than the No. 151.

Back in the October 2002 issue of Fine Woodworking Magazine, chairmaker Brian Boggs wrote a great article titled, “Soup Up Your Spokeshave” that should be helpful in making your vintage (or even new) spokeshave work as good as possible (find the article here).

- Here are some excellent vintage spokeshave models that should be easy to find:

- View Stanley No. 151 spokeshaves on Ebay

- View Stanley No. 51 spokeshaves on Ebay

- View Record A151 spokeshaves on Ebay

- View new Stanley No. 151 spokeshaves on Amazon

- Here is an Ebay search for used spokeshaves that have sold, so you can get an idea of the current going price for different models.

What are the Best New Spokeshaves for Woodworking?

A well-respected chair maker, Brian Boggs, designed an excellent curved-bottom spokeshave for Lie-Nielsen. This is my favorite new spokeshave. The A2 blade keeps a good edge and the castings are nicely machined with a flat bed and cap iron, which all lead to a chatter-free tool that helps prevent tearout. The hickory handles are comfortable and appropriately shaped. The Lie-Nielsen spokeshave comes totally tuned, sharp, and ready to use out of the box. You can buy it here.

Cheaper, new spokeshaves are rarely usable out of the box. But as mentioned earlier, here’s an excellent Fine Woodworking article by Brian Boggs, called “Soup Up Your Spokeshave” where he shows how to improve a newer, cheaper spokeshave (Issue #158, pp. 45-49).

Stanley has manufactured a “reproduction” of their vintage No. 151 spokeshave (pictured above). Though not made as good as the original (maybe they lost the recipe?) with some work and modifications it can do a pretty good job. You can also use your belt sander to round the bottom. You can find it on Amazon here. (sold under model numbers 12-951 and 1-12-151 for $25-$35). But it’s going to require just as much work (if not more) than a vintage No. 151, so you might as well buy a vintage model and put some work into it, and get a better spokeshave.

Other new Spokeshave options: Highland Woodworking has a good selection of new spokeshaves and replacement blades here. I have heard good things about the Veritas Low Angle Spokeshave, found at the above link. I would steer clear of the Kunz spokeshaves, as I haven’t had luck tuning them up.

RELATED

Which 20 Woodworking Hand Tools Should You Buy First?

Why Traditional Hand Tool Woodworking?

10 Jaw-Dropping Woodworking Shop Tours

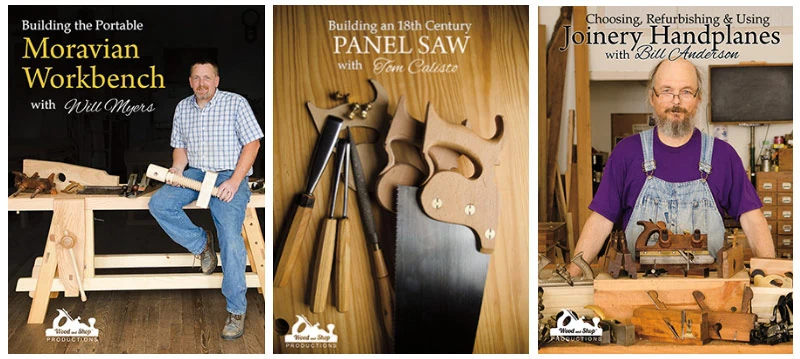

57 Page Moravian Workbench Plans Now for Sale

How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

8 Steps to Cutting Dovetails with Woodworking Hand Tools

Buy Hand-stitched Rasps and Files

A rasp is often confused with a metal file. A file is used for working metal, or for smoothing wood, but a rasp is used for shaping wood. If used correctly, rasps do amazing work at fairing curved surfaces and shaping areas with difficult grain, that an edge tool would tear out.

Rasp “Grain” explained

Just like sandpaper grits, rasps come in different levels of coarseness, on a gradient from course to fine. Typically the scale runs from 1 grain (most coarse) to 15 grain (most fine). Rasps with 6 grain and up are used for woodworking.

What should you look for in a Rasp?

So what features should you look for when buying a Rasp? The first most important consideration is to buy a rasp that doesn’t have uniform rows of teeth. When rasp teeth sit one behind another, the rasp will not give an even cut, but will dig in and put a pattern in the wood, just like when you bite into an apple. Machine made rasps have teeth like this. “Hand stitched” rasps (hand punched teeth) have random, nonuniform teeth, which give a much cleaner surface on the wood.

The rasps I use are half-round: a flat face and a rounded face. The flat face is used for flat and convex surfaces (i.e. hills) and the rounded face is used for concave surfaces (i.e. valleys).

Here are the rasps that I own, and recommend:

Cabinet Maker’s Rasp

A cabinet maker’s rasp is used for more course, quick removal, to get close to a layout line. I would recommend buying a “Cabinet Maker’s Rasp” that is 9-10 inches long with a grain of about 9-11. Nicholson used to make a good cabinet maker’s rasp, which was the standard, but since outsourcing its manufacturing to Brazil, the quality has suffered. You can read this article by Joel Moskowitz, the owner of Tools for Working Wood for more details. So for now (per my experience and the experience of friends) the only quality manufactures of hand stitched rasps appears to be Auriou, Liogier (fastest cutting albeit a bit rougher finish), Corradi, and perhaps Gramercy.

I own a 10-inch / 9 grain Auriou Cabinet Maker’s rasp (find it here). This more course Cabinet Maker’s rasp helps me quickly remove and shape a lot of wood, whether I’m making table legs or saw handles. I use it all the time.

Modeler’s Rasp

The modeler’s rasp is finer than the cabinet maker’s rasp, and is used to do the finish work, and remove the large scratches from the cabinet maker’s rasp. They are usually 6-9 inches long, and come in 13-15 grain. I personally own an Auriou modeler’s rasp: 7-inches, 13 grain (find it here).

Other Specialty Rasps

In addition to the above-mentioned rasps, I own a saw maker’s rasp, for getting into tight curves, especially when making saw handles. Some people recommend buying a rat tail rasp, for use on hollow shapes and in coping moldings (13-15 grain).

Files for Curved Work

On some projects, the modeler’s rasp provides a finished surface, but most of the time I need a finer finish. This is where smooth cut files come in. I recommend using the Nicholson 6″ half-round double cut smooth file, available here on Amazon. I then follow the filed finish up with finer grits of sandpaper.

Buy a Drawknife

What is a Drawknife?

A draw knife is a very useful tool for both rough cuts, to break down green wood into a rough shape, and for refining cuts. It’s the main tool used on a shave horse. The woodworker holds both handles, and pulls the drawknife toward their body, shaving wood off the workpiece.

What to look for in a Drawknife?

Different people have different preferences when it comes to drawknives, but Windsor Chair maker Elia Bizzarri prefers a drawknife that tapers slightly toward the cutting edge. He said that a thinner blade offers the ability to get a shorter blade bevel, which means it will get into concave surfaces more easily. He said that this feature isn’t so important for shaving chair spindles, but more so for the curved surfaces of a windsor seat.

Elia said that a drawknife can be used either bevel down or bevel up, but he prefers to use it bevel down. But if using a drawknife with the bevel up, the back can’t be dead flat, but needs to be slightly rounded, so that the drawknife won’t get stuck, and can come up out of the cut. If you prefer using it bevel down (like Elia), then a flat back is prefered. This makes sharpening easier.

The desired handle angle also depends on if you choose to use your drawknife bevel down or bevel up, because you want your wrist to be straight when working. So, for example, if you found a drawknife at a flea market, and you wanted to use it bevel down, you could sit in a chair, hold it out in front of you at waist height, and see if the handles allow you to keep your arms straight when the bevel is down.

Here’s a great article by Curtis Buchanan called, “How to Sharpen and Use a Drawknife” (Fine Woodworking issue #268). By the way, Elia Bizzarri apprenticed under Curtis Buchanan.

Where to find a Drawknife?

There are a few modern tool companies who make drawknives, but antique drawnives they can be found at quite reasonable prices if you hunt around at flea markets, yard sales, or antique stores. Drawknives were a more common tool, that was used extensively on farms. Below are some ideas of where to find antique and new drawknives:

- The first place to find antique drawknives is at farm sales, estate sales, flea markets, antique stores. But if you don’t have time to hunt them down that way, try buying online:

- Search antique drawknives on Ebay

- Search new drawknives on Highland Woodworking (this is the best selection of new drawknives)

- I looked at a lot of drawknives on Amazon, and they didn’t appear to meet the standards for a good draw knife.

Buy a Compass Plane / Circular Plane

A compass plane (i.e. “circular plane”) is used for smoothing a concave or convex surface, like the edge of a round table top. The top knob can be turned left or right to adjust the arc of the flexible plane sole, in a convex or concave direction. I wouldn’t consider a compass plane, like this Stanley No. 113 compass plane to be an essential tool. While they are fun to use, and they look cool, I haven’t found them to be any more useful than using a spokeshave. Maybe I haven’t given my compass plane a fair shake, but I get by just fine with a spokeshave. But if you stumble across an affordable compass plane like this Stanley No. 113 or even a non-adjustable wooden compass plane, you may just want to give it a chance.

Continue to the Buying Guide for Green Woodworking Tools (#10)…

TOOL GUIDE SHORTCUTS:

HAND TOOL BUYER’S GUIDES

- Intro to Buying Woodworking Hand Tools

- Workbench & Tool Storage

- Layout, Marking, & Measuring Tools

- Handplanes

- Handsaws

- Chisels

- Sharpening & Honing Supplies

- Mallets & Hammers

- Hand Drills, Braces, & Bits

- Tools for Curved Work

- Tools for Green Woodworking

- Woodworking Clamps, Gluing & Fasteners

- Tools for Wood Carving

- Products for Wood Finishing, Sanding & Scraping

- Wood Turning Tools & Lathes

I would add Hock’s Spokeshave kit to the mix of good new products. Of course the end result for the kit is dependent on the care taken to build the kit, but you won’t go wrong with a Hock blade.

Thanks for your input Joe!